Here are 10 important things to consider when transporting your wine to market.

Canopy contacted the IWC’s new shipping partner, Hillebrand Gori, to get the inside track on maintaining wines in tip-top condition while transporting them in the most efficient, sustainable and economic way possible.Are temperature fluctuations the main reason for wine spoilage during shipping?

During transportation, temperature extremes are the single biggest danger to your wine – so it needs to be stored at a range between +10°C and 20°C (+50-68°F).

That’s why it’s important to consider your shipment’s route. Is it moving across continents, departing in one season and arriving in another? A wine imported from Australia to the UK, for example, could spend 48 days in transit, leaving Adelaide during the Southern Hemisphere’s winter, crossing the equator, and arriving in London in the Northern Hemisphere’s summer.

Ideally, the temperature should remain between 12-14°C (53.6-57.2°F). A 10°C increase in the storage temperature can double the ageing process, according to Hillebrand Gori. The wine could lose its freshness and taste sour and flat. The colour may change with a noticeable increase in browning. Heat damage will also reduce ageability.

In addition, when temperatures climb outside, liquids contract in volume within the bottle. This can affect the integrity of corks and cause glass bottles to crack or leak from pressure buildup inside.

Temperature drops also affect wine. If a wine experiences temperatures between +5°C and 10°C (41-50°F), tartaric precipitation might create a crystalline sediment inside the bottle. At very low temperatures (-7ºC to -10ºC), wine might freeze and push the cork out of the bottle, or even crack the glass.

What other potential problems are there?

Humidity is also an issue. The ideal relative humidity for wine preservation is around 70%, but this can be different depending on the wine itself. Humidity levels of 55-80% are recommended for fine wines, but below 50% humidity is best for commercial wines. During transport, wine can be exposed to extremes in humidity as well as temperature.

High humidity levels can cause mould growth on the wine bottle exterior and on the cork, which can contaminate the wine. Contrastingly, over time, low relative humidity can cause cork to contract and dry out, reducing its ability to seal wine bottles. It can also cause cork to crumble when the wine is opened, reducing customer satisfaction.

During shipping, excess humidity can also lead to ‘container rain’. This can occur when the temperature inside a container becomes cooler than the air outside the container. This moisture can drip down onto your wine, ruin the labels and result in spoilage.

Vibration during storage, handling, or transport is also generally considered bad for wine. Vibrations, even for a short period of time, can alter the quality and organoleptic properties of the wine, including its aroma. Excessive levels of vibration can increase the acidity of red wines, lead to an accelerated decrease in tannins, and lower the alcohol content of the wine.

Light exposure can cause lightstrike, especially in sparkling, white and pale rosé wines. This can happen at any stage of the shipping, storage or even sales process.

Contamination is a potential problem if your container was previously used to transport other goods. It could taint your wine’s taste and aroma.

How can we avoid these potential problems?

The obvious solution is to transport your wine in temperature-controlled containers.

A refrigerated container or “reefer” allows wine to maintain an exact temperature during transport. The installation of a refrigeration unit on the container ensures cool air circulates internally.

A more budget-friendly option is to install an insulated liner within a standard container. Insulation liners shield and preserve wine from thermal shock. Hillebrand Gori says its insulation liner limits temperature increases to an average of 8-11°C (14-20°F) and saves 23% on CO2 emissions compared to a refrigerated container.

To get an idea of the likely temperature variations facing your shipment on a particular route, you can use meteorological data from the World Meteorological Organization to predict the likely temperature and humidity levels. Hillebrand Gori says the data is so comprehensive that the average, maximum and minimum temperature can be shown for any ship date on any route. Accurate forecasting means you can better plan how to transport your products and the protection they need for a safer journey to destination.

What is the best way to ship wine?

There are various ways to ship wine over long distances, all with pros and cons for wine preservation, as well as cost and speed.

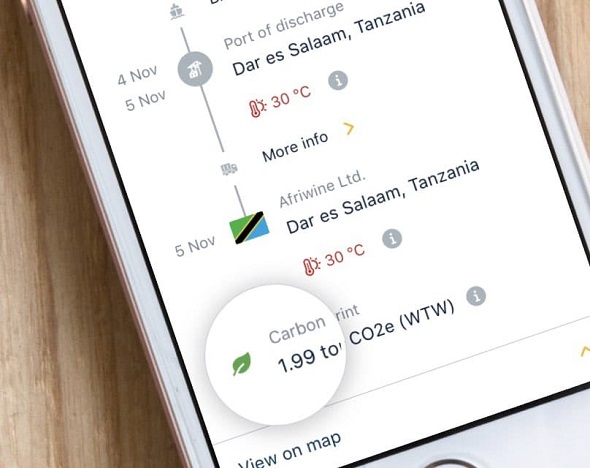

Sea freight is the most carbon-efficient mode of transport. It’s also economical for any size of wine shipment, from bottles to cases to pallets, making it the prime choice for international freight shipping.

Air freight is the fastest – and probably most secure – way to transport, from a single bottle to 100 tons of wine pallets. There is also little fluctuation in temperature and humidity on the journey.

Rail is often overlooked. Rail transport is swift, dependable and rarely delayed. Terminals are also highly secure spaces so the risk of theft is extremely low. Rail freight is also a greener logistics option compared to road freight. But there’s usually a slightly longer overall lead time.

At some point, road transport will be involved. It’s the standard way to transport wine short distances.

What’s the best container for shipping wine?

The earliest examples we have of wine storage are animal skins, clay jars and amphorae. For thousands of years, these vessels were used by ancient civilizations to store and protect their wine. Later, when the Romans conquered Gaul, they found the natives storing their beer in wooden barrels. These were stronger, lighter, and more portable, so the Romans quickly adopted them to store their wine instead of amphorae.

The next big leap came in the 17th century with the invention of thick glass bottles. These gave wine more protection against oxidation than barrels and were durable enough to allow wine to be safely moved by horse and cart along rough roads. This development was so successful that we still ship wine in glass bottles today, although now we have lightweight glass options that mean a lighter payload, which is better for the environment.

Cased bottles of wine still require careful handling and protection. Insulated and refrigerated containers offer additional temperature protection compared to a standard dry shipping container.

Hillebrand Gori sees growing interest in replacing bottles on pallets with a flexitank, which sits inside a dry container, so that you can transport more than double the wine carried in a single 20ft container. This is also one of the safest and most cost-effective ways to move wine. Hillebrand Gori’s flexitanks are designed with a protective barrier to prevent oxidation and keep out taint compounds. Wine transported in a flexitank is also less susceptible to temperature shocks due to the volume of the liquid carried.

Is it worth insuring the shipment?

While cargo insurance isn’t mandatory, it’s highly recommended. “Consider the value, not the insurance premium” is the advice from Hillebrand Gori, which offers its clients insurance in partnership with Willis Towers Watson.

Insurance ensures you’ll be covered financially for any losses if something happens during transit, like theft or damage.

One risk factor to be sure your insurance policy covers is ‘general average’ (GA). Maritime law grants an ocean carrier the right to declare GA if their vessel must take extraordinary measures to make a situation on board a container vessel safe. It’s a voluntary sacrifice of cargo in response to an emergency like a fire or where a ship has run aground. The loss and associated expense incurred by the shipper of those containers is distributed among all the shippers with cargo on that vessel.

Is it better to fill a container?

Whether you choose a full-container-load (FCL) or less-than-container-load (LCL) service depends on the quantity of wine you want to ship. FCL is the right option when you’re transporting a full 20ft container shipment of 10 VMF pallets or 11 EURO pallets, for example.

Advantages of FCL over LCL include: a faster journey; reduced warehouse handling time; reduced risk of damage; faster clearance procedures at customs; cross docking opportunities; and choice of container type.

However, FCL is not the best option for small quantities. LCL allows multiple shippers to share the capacity and cost of a container. Shipments are gathered from different suppliers and consolidated into a single shipment that is loaded into one container. This means you only need to pay for the exact amount of pallets you want to ship without having to fill an entire container yourself. You can send anything from a single case to several pallets.

Hillebrand Gori, by the way, will only consolidate your wine with other wine, beer or spirits shipments to eliminate the risk of cross contamination.

Are there any restrictions regarding pallets?

When shipping wine internationally using wooden pallets, you must follow phytosanitary standards. International Standards for Phytosanitary Measures no15 is an international standard for wooden pallets. It requires wooden pallets be heat-treated or fumigated to eliminate pests and diseases before they are used. If you transport beverages on an untreated pallet, customs authorities can reject your shipment, and/or the wine producer can be fined.

With road freight transport, it’s worth remembering that the maximum weight you can fill a container to is not necessarily the maximum weight you are able to fill your container to. The weight of a full 20ft container of wine, for example, may exceed the legal weight limit for some of or all the journey. Road weight limits vary depending on the country, state and sometimes even the region your wine is transported within.

What’s the container market like now?

The container availability bottlenecks seen in 2020-2021 began to ease in 2022 when demand began to settle and port congestion eased. Demand continued downwards in 2023, and the container market now has a surplus of 6 million TEUs (20ft equivalent units) globally.

‘The cost of transportation by sea is higher at the moment’With most shipping companies currently avoiding the Suez Canal, what impact is this having on shipments of wine from the Northern to Southern Hemispheres?

In a nutshell, transit time is longer and an emergency surcharge is in place – meaning the cost of transportation by sea is higher at the moment.

Hillebrand Gori’s procurement team told Canopy: “2024 begins with a challenging ocean freight outlook. As the Red Sea situation continues, some 5 million TEU are sailing on longer routes around Africa. When most vessels remain diverted from the Suez Canal in the foreseeable future, transit times and sailing schedules are disrupted. Additional vessels needed represent 5-6% of worldwide capacity, and emergency surcharges have been imposed by all carriers. It’s an extremely volatile situation and one that requires a collective approach to overcome.”

English

English French

French

.png)