The shorter maceration time means a reduced chance of oxidation, which can lead to undesirable flavours and aromas. Ultrasonic treatment (sonication) causes the cells in the skin of the grape to rupture, allowing the desirable compounds to be extracted in a significantly shorter time.

Ultrasound technology is being touted as a transformative force in modern wine production, offering substantial benefits across the entire winemaking process. These include:

- Its ability to reduce maceration time while achieving superior extraction of phenolic compounds and aromatic elements;

- Precision controllability and monitoring capabilities ensure consistent quality across different wine varieties, from robust reds to delicate whites and rosés;

- Economic advantages, such as energy savings and significant improvements in production efficiency due to a quicker turnaround of tanks;

- Enhanced organoleptic properties.

Let’s take a closer look at this advancement and see if it marks a significant step forward in wine production.

Is ultrasound technology the next big thing in winemaking?

Temperature-controlled maceration and micro-oxygenation techniques have emerged as standard but powerful tools for enhancing wine characteristics. Is ultrasound technology – which has been widely employed in the food industry to improve processing methods such as gelation or crystallization – the latest breakthrough?How it works

The International Organization of Vine and Wine approved ultrasound use for pre-fermentation maceration five years ago, acknowledging its effectiveness in compound extraction. This innovative technology operates through controlled cavitation, where ultrasonic waves create microscopic bubbles that collapse and release energy, facilitating the extraction of desired compounds from grape skins.Modern ultrasound systems, operating at specific frequencies (typically above 20 kHz) and power levels, demonstrate remarkable efficiency in extracting colour pigments, tannins, and aromatic compounds.

Here is an example of the equipment. This was the star product on Spanish manufacturer Grupo Agrovin’s stand at this month’s SIMEI 2024 exhibition in Italy. The La Mancha-based company says its Ultrawine Perseo is “setting the path toward the future of wine production”.

The principles of ultrasonic extraction

Cavitation mechanisms: The core principle of ultrasonic extraction relies on acoustic cavitation, which occurs when ultrasound waves pass through the grape must. This process generates microscopic bubbles that undergo rapid formation, growth, and violent collapse. These cavitation bubbles create extreme localized conditions, producing pressures up to 1000 atmospheres and temperatures reaching 5000°C at the microscopic level.Soundwave interactions: Ultrasonic waves in wine processing operate within specific frequency ranges, each producing distinct effects. Frequency range 20-100 kHz causes “high-power extraction and mechanical effects” while 100 kHz-1 MHz leads to “enhanced mass transfer, reduced mechanical damage”. The mechanical effects of soundwaves cause significant structural changes in grape tissue. When cavitation bubbles collapse near grape skin surfaces, they generate microjets that penetrate cellular structures. This action increases membrane permeability and accelerates the transfer of compounds from grape skins – and possibly seeds – to must.

Temperature effects: Temperature plays a crucial role in ultrasonic extraction efficiency through multiple mechanisms. The thermal energy contributes to breaking solid-phenol bonds by overcoming activation energy barriers, with higher temperatures enhancing the extraction process.

What are the optimal ultrasound parameters?

Successful implementation of ultrasonic technology in wine production requires precise calibration of multiple parameters. Research demonstrates that optimal extraction results from carefully controlled combinations of frequency, power, and duration settings.Frequency selection: The selection of ultrasonic frequency significantly influences extraction efficiency in wine maceration. Operating frequencies between 20 kHz and 28 kHz prove most effective for phenolic compound extraction. Lower frequencies produce stronger mechanical effects, while higher frequencies enhance chemical reactions through radical formation.

Power intensity control: Power settings directly affect extraction intensity and must be carefully controlled to prevent unwanted effects. Research indicates optimal power ranges:

- 150-200W – gentle extraction for delicate varieties

- 200-300W – standard processing conditions

- 300-400W – enhanced extraction for robust varieties

Treatment duration: This is a critical parameter but varies based on grape variety characteristics, desired compound extraction levels, power intensity settings, and processing temperature. Some microvinifications achieve the desired results in as little as a few minutes or couple of hours. In general, the research indicates that maceration time can be reduced by 40-60% with ultrasound waves. Extended treatments do not necessarily yield proportional benefits.

Modern ultrasonic systems incorporate precise control mechanisms that allow winemakers to adjust these parameters based on specific varietal requirements and desired wine characteristics. This technological advancement enables consistent results across production batches while maintaining energy efficiency, with some systems demonstrating up to 15% energy savings compared to traditional maceration methods.

What style of wine benefits most from ultrasound treatment?

Ultrasonic technology demonstrates remarkable versatility across different wine styles and varieties. But it’s clear that the processing parameters require precise adjustment based on grape characteristics and desired wine profiles.Red wine production benefits significantly from ultrasonic treatment. Research suggests it improves the quality of red wines in terms of phenolic, aromatic, and polysaccharide extraction, giving rise to wines with a more intense aroma and greater complexity. The technology shows exceptional results with thick-skinned varieties like Cabernet Sauvignon and Monastrell. Studies demonstrate that ultrasound-assisted maceration achieves comparable phenolic extraction in 72 hours versus seven days with traditional methods.

Research also indicates a 35-40% increase in organoleptic attributes when using optimised ultrasound parameters for red varieties. The technology proves particularly effective in managing climate change-affected grapes, enabling quality wine production even with varying grape maturity levels.

White wine processing requires more delicate ultrasound application to preserve aromatic compounds and prevent oxidation. The technology demonstrates effectiveness in enhancing thiol precursor extraction while maintaining protein stability (for improved shelf life). Modern ultrasonic systems operating at 20-30 kHz with controlled amplitude settings have achieved optimal results without compromising wine clarity.

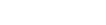

While most of the studies I looked at focused on red and white wines, some researchers in Spain have checked out the benefits for rosé wines. A team from the University of Castilla-La Mancha and the University of Murcia in Spain used high-powered ultrasound technology to treat crushed Monastrell grapes and compared the resulting rosé with the wine obtained after a four-hour maceration period. The results, published in the Journal of the Science of Food and Agriculture, found improvements in colour and aromas. “Sonication resulted in wines with intense aromas of red fruits and flowers, with higher scores than wines from macerated grapes,” the study said.

Analysis of the chemical composition supported this claim: ultrasonication improved the extraction of several volatile aroma-enhancing compounds, such as terpenes, which can give off a floral or citrus fragrance.

Here’s how a panel of tasters characterised the rosé wines

Looking at the sensory analysis of control and treated wines.

CW = control wine; MW = wines from short skin maceration; USW = wines from ultrasound maceration. (*) denotes significant differences according to ANOVA test (P ≤ 0.05).

Sweet and sparkling wines could also benefit from customised ultrasonic treatments as it can accelerate the ageing process, achieving desired sensory profiles in reduced timeframes.

Modern ultrasonic systems incorporate variety-specific programming options, allowing winemakers to adjust parameters based on grape characteristics and desired wine profiles.

What’s the economic and market impact?

Analysis of market data reveals substantial commercial advantages for wineries implementing this innovative approach to maceration.Production efficiency gains: The implementation of ultrasound technology demonstrates remarkable improvements in operational efficiency. Studies indicate energy savings of up to 15% compared to traditional maceration methods, while simultaneously reducing production time by up to 50%. The reduction in processing time enables higher tank rotation rates, effectively increasing production capacity without requiring additional infrastructure investment. This efficiency translates directly to improved operational margins and enhanced production flexibility.

Market differentiation opportunities: Wineries adopting ultrasound technology position themselves at the forefront of innovation in an increasingly competitive market. The technology enables producers to differentiate their products through several key advantages:

- Enhanced product quality with a 35-40% increase in organoleptic attributes;

- Reduced reliance on chemical additives and preservatives;

- Improved shelf life and product stability;

- Environmental sustainability credentials.

The downside of this technology

The cost is the main inhibitor. Other considerations are the need for staff training and experimentation. You will also need comprehensive monitoring systems and standardised testing protocols for total anthocyanin content, phenolic compounds, colour stability, and volatile compounds.The bottom line

This technological advancement enables consistent results while maintaining the distinctive attributes of each variety, representing a significant evolution in wine production methodology.It also appears to be relatively easy to integrate with traditional winemaking equipment without losing production efficiency or wine quality.

But it’s the technology’s ability to address multiple market demands – from production efficiency to sustainability concerns and improved wine quality – that really positions it as a significant force in shaping the future of wine production.

Especially as market analysis reveals that wines produced using ultrasound technology can command premium pricing, particularly in segments where consumers prioritise innovation and sustainability. The technology’s ability to enhance natural flavour profiles while reducing chemical additives also resonates strongly with today’s premium wine consumers.

English

English French

French

.png)